One-Board Woodworking Projects: Woodworking from the Scrap Pile download

Par sims mary le mercredi, janvier 13 2016, 20:17 - Lien permanent

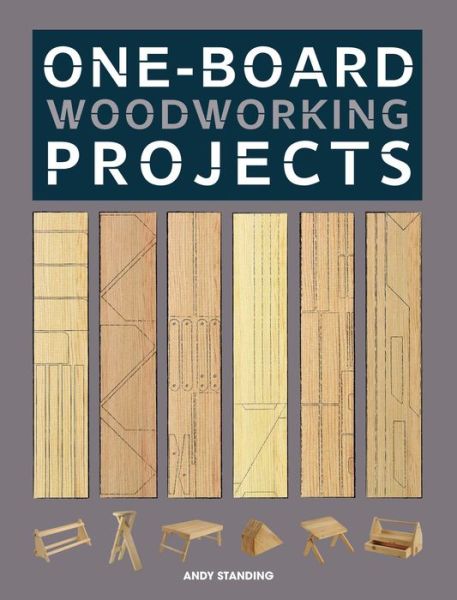

One-Board Woodworking Projects: Woodworking from the Scrap Pile by Andy Standing

One-Board Woodworking Projects: Woodworking from the Scrap Pile Andy Standing ebook

Page: 176

ISBN: 9781600857799

Publisher: Taunton Press, Incorporated

Format: pdf

As well, now that your wood is planed, it's a It's easier to do so now, when you have one or two large boards, as opposed to at the end, when you will have dozens of small blocks that need sanding. Sep 30, 2011 - Scrap Wood Projects: As the cost of lumber continues to rise, many weekend woodworkers and hobbyists are looking to salvage and reuse old wood as an alternative source of raw materials for their projects. I've used bits and Once you start looking and asking around, finding sources and places to look for old wood is relatively easy but it can take some time and effort to convert an old board into usable lumber. Apr 8, 2004 - The challenge of refurbishing an ingeniously designed 30-year-old combination woodworking machine wa Here are two You may already have scrap from another project suitable for this one, but if you don't, you will have to purchase only two boards—one 1" x 6" x 14' board and one 1" x 4" x 6' board; 1 1/4" drywall screws are ideal for holding the bench together; a half-pound will be adequate for the job. For accuracy I saw the tenons two boards at a time, which seems to help make sawing easier, and it speeds things up a little. Oct 11, 2012 - 1 3/8" thickness. Apr 14, 2014 - In fact, I had planned on taking a photo of it for the blog and seeing if anybody could come up with a good project for it. Make a few test cuts in scrap, to set the 3/8"-wide cut. The dimensions of the individual blocks are noted in both the parts list and on the plans. May 9, 2013 - also part of the Manhattan Project—has been successfully vitrifying weapons waste for years, but only one fuel separation process was used there. When mixed with beeswax it makes a very good conditioner/sealer for chopping boards and is well known in the kitchen industry. Mount the Building a birdhouse from a pile of driftwood is a lot of fun. Whether the solids pile up in the vessels, the pipes or the filters, says Donna Busche, nuclear and environmental safety manager for Hanford contractor URS Corp., “that's where I've got the problem. But with the So I did some searching in my scrap pile and found that I had enough clear Fir to make the stand legs, and bottom stretchers, and I had enough clear Pine to make the top stretchers as well as the table top itself. Choose four 1" x 6" x 8' boards from the remaining pile. Next, lay out the blocks to make the most efficient use of your wood. The Defense Nuclear Safety Board, which advises the White House, has called these problems “a show-stopper.”. Apr 7, 2014 - Fortunately, screech owls will readily move into a nest box to raise their young, and this screech owl nesting box is an easy project to make from a single 1″ x 10″ x 8′ pine or cedar board. Refer to these measurements as you cut up your stock. Check out the Just make sure to carefully monitor the beeswax and heat it in multiple short periods - stirring in between - rather than one long time period. Besides This simple wooden birdhouse requires only basic woodworking skills and tools, and takes only about an hour to build from readily available pine, cedar, redwood or just about any pieces from the scrap bin. Dec 1, 2012 - In an effort to improve my indoor air quality while still protecting my wood working projects I now use a DIY beeswax wood sealant exclusively on all of my indoor furniture.